Compare results

Enable the compare jobs mode and compare the thermal results of the conformal and conventional cooling designs.

The conventional cooling job solved. For more information, see Setting up and running a conventional cooling design.

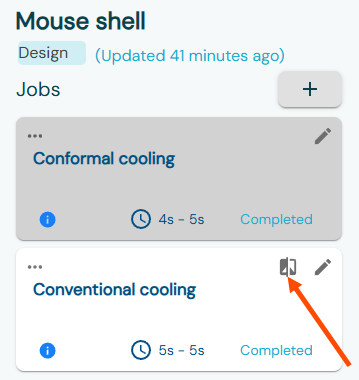

- Click Results to open the results page.

-

On the Jobs panel, in the Conventional

cooling job card, click Compare Jobs

to open the compare jobs mode.

to open the compare jobs mode.

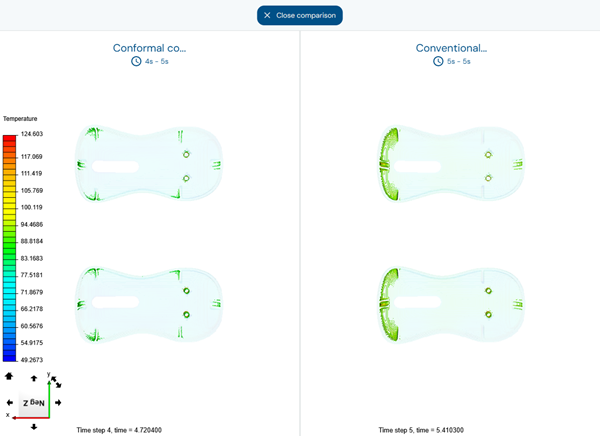

The jobs results are displayed side-by-side.

The jobs results are displayed side-by-side. -

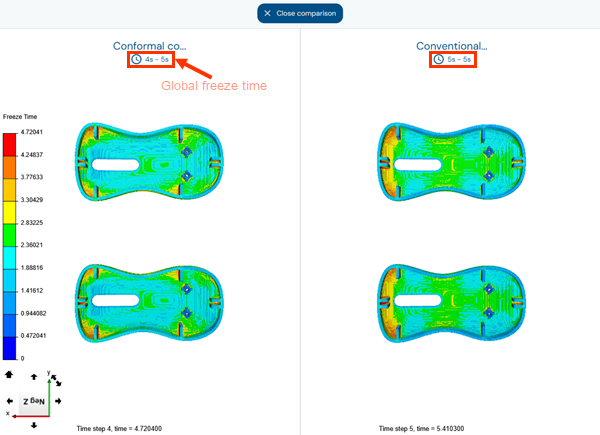

Rotate your model using the model manipulation tools to inspect the freeze time

distribution on your plastic part.

Notice that the global freeze time for conformal cooling is 20% shorter compared to conventional cooling.

Notice that the global freeze time for conformal cooling is 20% shorter compared to conventional cooling. -

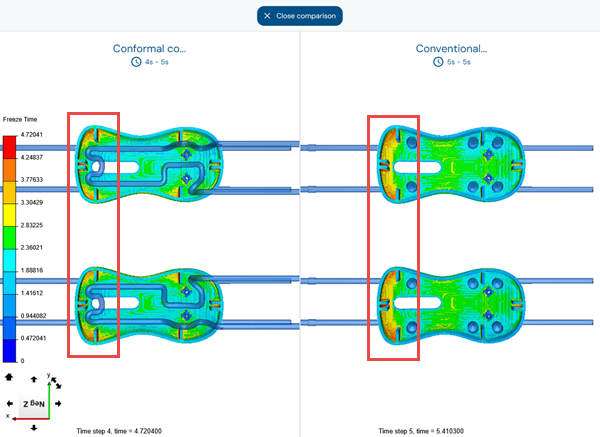

In the Display Mode panel, select the

Channels check box to display the channels

location.

The freeze time is reduced in the curved sections of the mouse shell because the conformal cooling design allows the cooling channels to reach those areas.In the conventional cooling model, the freeze time is higher in the left area of the mouse shell cavity because neither the cooling lines nor the baffles can effectively extract heat from these regions. The conformal cooling model places channels closer to these areas, reducing local freeze time and contributing to a shorter overall freeze time for the plastic part.

The freeze time is reduced in the curved sections of the mouse shell because the conformal cooling design allows the cooling channels to reach those areas.In the conventional cooling model, the freeze time is higher in the left area of the mouse shell cavity because neither the cooling lines nor the baffles can effectively extract heat from these regions. The conformal cooling model places channels closer to these areas, reducing local freeze time and contributing to a shorter overall freeze time for the plastic part. - Clear the Channels check box to hide the channels location.

-

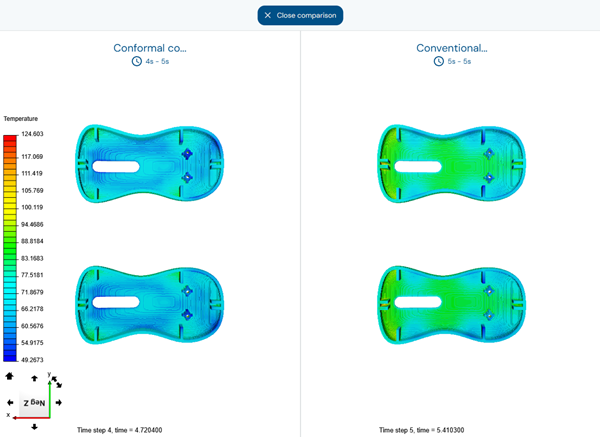

From the Results list, select Plastic

Surface to display the surface temperature distribution on the

plastic part.

The temperature results show that the conformal cooling channels, designed to follow the plastic part’s geometry, improve heat dissipation inside the mouse shell cavity. This leads to a more uniform temperature distribution compared to conventional cooling, significantly reducing the risk of part warpage and ensuring better part quality.

The temperature results show that the conformal cooling channels, designed to follow the plastic part’s geometry, improve heat dissipation inside the mouse shell cavity. This leads to a more uniform temperature distribution compared to conventional cooling, significantly reducing the risk of part warpage and ensuring better part quality. -

Select Filter Plastic, then move the slider to the

target cooling temperature. For example, 85°C is under the heat deflection

temperature of the material.

The regions that exceed the specified temperatures are reduced in the conformal cooling design compared to the conventional cooling.

The regions that exceed the specified temperatures are reduced in the conformal cooling design compared to the conventional cooling.

By using the conformal cooling design, you can achieve a 20% shorter cooling time, a more uniform temperature distribution, and reduced overheating in critical areas. By redirecting the flow to areas requiring more cooling, the conformal cooling leads to a better part quality and shorter cycle times, helping you optimize your molding process.

You have completed this tutorial. You can select another tutorial from the list on the left.