What's new—11 September 2025

This SimForm update was published on 11 September 2025 and includes several new features and enhancements listed on this page.

Beta features must be enabled to access certain SimForm capabilities. To request access, please email info@simform.app.

Project and job name updates

| Old name | New name |

|---|---|

| Feasibility Project | Part Evaluation Project |

| Design Project | Tooling Evaluation Project |

| Design job | Channel Assessment job |

Choosing your preferred temperature unit

You can now display temperatures in either degrees Celsius (°C) or degrees Fahrenheit (°F) throughout the application. This setting applies to all input and output temperature values, including material properties and results.

- Prerequisite: You must log in to SimForm.

- Command location:

Controlling the frozen wall thickness

In the Plastic Part card, you can set the Frozen Wall Thickness to specify the percentage of the part’s thickness that must solidify before it is considered safe to eject. This provides greater control over thermal simulation accuracy and part ejection timing.

Creating channels and baffles

You can now design and test different cooling channels layouts directly in SimForm, without having to import them from your CAD model.

With this feature, you can:

- Create new cooling channels and baffles in your mold design.

- Extend cooling channels to connect with existing CAD models and add baffles to them.

- Export the created channels and baffles as OBJ files using the Download OBJ Files command on the Results page. You can then use them in your CAD software.

Inspecting cooling channel results

For channel assessment jobs, you can now use the Cooling Channel Results table to evaluate thermal performance of each cooling channel in your model. It displays the following metrics for each cooling channel:

- Flow rate through the channel.

- Coolant temperature rise.

- Heat removal rate.

- Total heat removed.

- Total heat removed by all channels.

- Required heat removal to fully solidify the plastic parts.

You can also export the table as a CSV file using this format: <project_name>_<job_name>_channel_results.csv.

- Prerequisite: A solved channel assessment job.

- Command location: Job card

Using a channel design project (beta)

When beta features are enabled for your account, you can now use the channel design project to plan and iterate cooling strategies from data-driven recommendations. Within this project, you can create Feasibility, Channel Assessment, and Channel Recommender jobs.

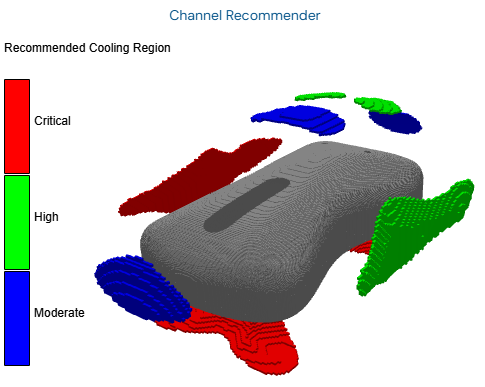

The channel recommender analysis uses a generative design algorithm to analyze your plastic part geometry and automatically recommends cooling line locations. These recommendations highlight the regions most critical to cooling performance and part quality.

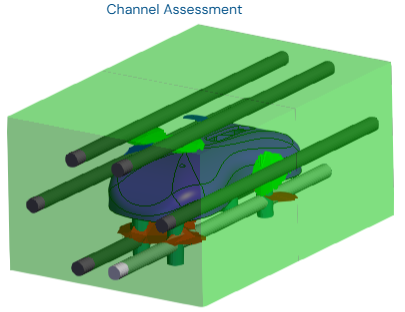

The following example shows the results of a channel recommender analysis for a computer mouse shell design. The recommended regions were imported into a channel assessment job where cooling channels and baffles were added using the SimForm construction tools.

|

|

Tooling evaluation project enhancements (beta)

When beta features are enabled for your account, you can now create Feasibility jobs in a Tooling Evaluation Project. Creating both feasibility and channel assessment analyses in the same project keeps geometry, materials, and boundary conditions consistent, so you can make faster decisions on cooling performance, cycle time, and part quality.