Injection molding overview

Use SimForm to perform thermal cooling analyses for your plastic injection mold designs. These analyses help you identify hot spots on the plastic part and develop cooling layouts to improve part quality and reduce cycle times.

Certain new SimForm capabilities are considered beta features and must be separately enabled to access them. To request access, please email info@simform.app.

Using a part evaluation project

The Part Evaluation Project allows you to create and run Feasibility jobs that you can use as a design-for-manufacturing (DFM) tool for your plastic part. You only need the CAD model of the plastic part.

You can run feasibility analyses for your plastic part design to:

- Predict hot spots and identify critical areas needing focused cooling.

- Estimate achievable cooling times before the mold is designed.

- Identify areas for design improvement to optimize manufacturing efficiency and improve part quality.

- Test different plastic part materials to quantify their impact on production cost.

Using a tooling evaluation project

In a Tooling Evaluation Project, you can create Channel Assessment jobs to run thermal analyses and iterate on preliminary cooling designs, including conventional and conformal cooling channels. You can also analyze and verify a complete mold design, predicting both part and mold temperatures and safe ejection times. This helps you optimize cooling channels and insert placement to enhance mold efficiency.

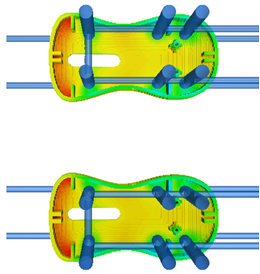

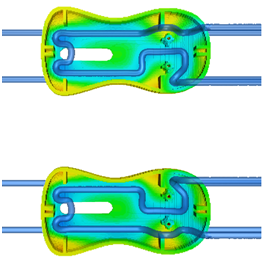

The following figures show a comparison of the temperature distribution using different cooling methods in a channel assessment job.

| Conventional cooling | Conformal cooling |

|---|---|

|

|

In a channel assessment job, you can run thermal simulations at different stages of the mold design process using:

- The basic mold feature that generates a rectangular mold around your plastic part to identify the hot areas in your plastic part that require cooling during the initial design phase, before designing the mold.

- A mold without cooling channels to identify high-temperature areas and critical components that need efficient cooling. This allows you to make well-informed decisions about the location for cooling channels and mechanisms like ejector pins and sliders in the mold.

- A mold with conventional cooling channels, including baffles and bubblers, to reach areas of the plastic part that cannot be cooled effectively with straight cooling channels.

- A mold with conformal cooling channels that follow complex shapes of plastic parts to determine whether the added cost yields a more efficient mold.

When beta features are enabled for your account, you can also create feasibility jobs in tooling evaluation projects. Creating both feasibility and channel assessment analyses in the same project keeps geometry, materials, and boundary conditions consistent, so you can make faster decisions on cooling performance, cycle time, and part quality.

Using a channel design project (beta)

When beta features are enabled for your account, you can use the Channel Design Project to plan and iterate cooling strategies from data-driven recommendations. Within this project, you can create Feasibility, Channel Assessment, and Channel Recommender jobs.

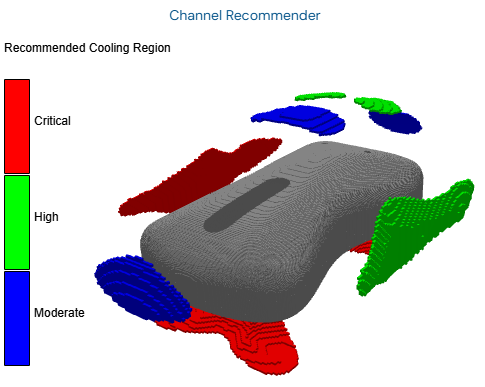

The channel recommender analysis uses a generative design algorithm to analyze your plastic part geometry and automatically recommends cooling line locations. These recommendations highlight the regions most critical to cooling performance and part quality.

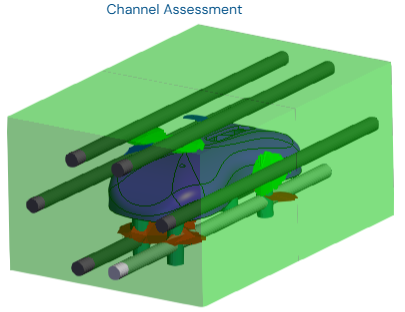

Within the same channel design project, you can import the channel recommender results directly into a channel assessment job. There, you can use the SimForm construction tools to create conventional cooling channels in the highlighted regions and run a basic mold simulation to evaluate the performance of the cooling layout.

The following example shows the results of a channel recommender analysis for a computer mouse shell design. The recommended regions were imported into a channel assessment job where cooling channels and baffles were added.

|

|

You can also download the recommended cooling regions as CAD models in IGES or STEP format. This allows you to import the recommendations into your CAD software to incorporate them into existing mold designs or use them as references during cooling design.

Optimizing mold material

SimForm projects allow you to test various materials for both the mold and plastic parts to optimize performance and reduce production costs. You can choose materials from a list of widely used materials for plastic injection molds and plastic parts, or define new materials to meet the specific needs of any plastic molding project.

Project pricing and job count

When you create a project, credits are deducted from your credit balance. Each project allows you to create a set number of jobs without using additional credits. If you exceed the maximum job count, you can create a new project to continue your analyses.

The number of required credits and maximum jobs depend on the project type, as shown in the following table.

| Project type | Credits | Maximum number of jobs |

|---|---|---|

| Channel Design Project | 20 | 12 (6 trial) |

| Tooling Evaluation Project | 10 | 12 (3 trial) |

| Part Evaluation Project | 3 | 6 (1 trial) |