Introducing SimForm

SimForm is a cloud-native tool for simulating injection and compression mold systems. It simulates the temperatures within your mold to assess the quality of the plastic part and predict the cooling cycle time. It lets you make informed decisions about your part and mold designs quickly and easily.

Why cooling matters

An effective cooling strategy is crucial for mold designs to prevent defects and reduce cycle times. Cooling can account for up to 80% of a part's total cycle time. Optimizing the cooling design with SimForm is essential for producing high-quality parts with shorter cycle times and reduced costs.

How SimForm works

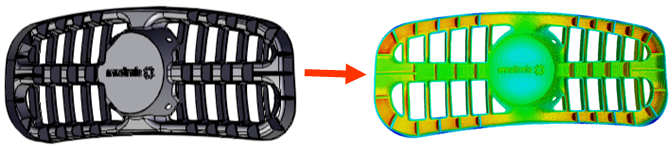

In SimForm, you can upload a CAD model of either the plastic part or both the plastic part and the mold. After identifying key components of the design, SimForm runs a simulation to highlight critical areas requiring cooling. You can then use the results to modify your cooling design in your native CAD software. This allows for quick iterations to achieve an optimized mold cooling design.

Use SimForm to:

- Choose an efficient cooling method by evaluating and comparing the performance of different cooling strategies such as drilled channels, 3D-printed conformal channels, baffles, bubblers, thermal pins, and inserts. Avoid overdesigns and the additional manufacturing cost of unnecessary components.

- Improve cooling channel placements by identifying critical areas that require additional cooling and optimizing the placement of cooling channels for better efficiency.

- Make informed material choices by comparing the heat removed by different materials, which helps you assess whether higher-priced alloy inserts or less-durable aluminum molds are cost-effective.

This allows you to shorten the development time, speed up the manufacturing process, and reduce costs without compromising quality.

Supported plastic molding industries

You can use SimForm to design and optimize your mold cooling designs for the following plastic manufacturing processes.

- Injection molding

- A molding process where molten plastic is injected into a mold cavity, cooled, and solidified to form a specific shape.

- Compression molding

- A molding process where partially molten plastic is placed on a heated mold and conforms to the shape of the cavity as the mold closes.

Efficiency, accessibility, and scalability

SimForm is a web application that you can access anywhere from a browser, without requiring installation. Product updates are free and accessible immediately. The straightforward interface allows you to define your model efficiently, and cloud computing delivers simulation results quickly. SimForm uses an automatic meshing process and a state-of-the-art thermal solver to perform full transient thermal simulations. It allows you to present and share information with colleagues and customers through the app, regardless of geographic location.