Define the mold

Categorize your mold components to allow the solver to identify them. You will then define their materials.

-

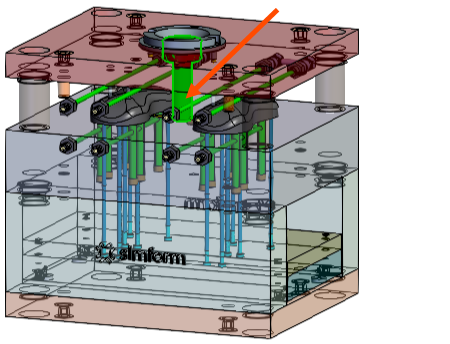

In the display window, select the mold cavity.

-

In the Mold Group 1 card, click add

to assign the cavity as a part of mold group 1.

Click expand

to assign the cavity as a part of mold group 1.

Click expand to view the list of added components for

verification. If necessary, you can click remove

to view the list of added components for

verification. If necessary, you can click remove  to remove a categorized component from the mold

group.

to remove a categorized component from the mold

group. -

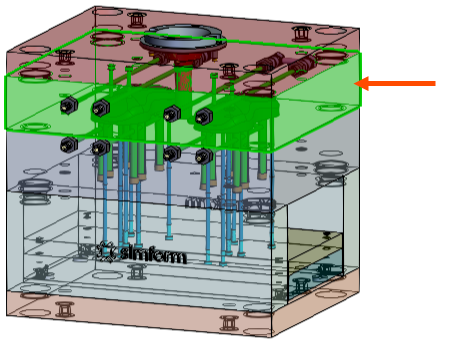

In the Mold Group 1 card, click hide

to hide the categorized component to verify that

your components are correctly categorized.

to hide the categorized component to verify that

your components are correctly categorized.

-

Repeat steps 2 and 3 to select the sprue bushing and add it as a part of

Mold Group 1.

-

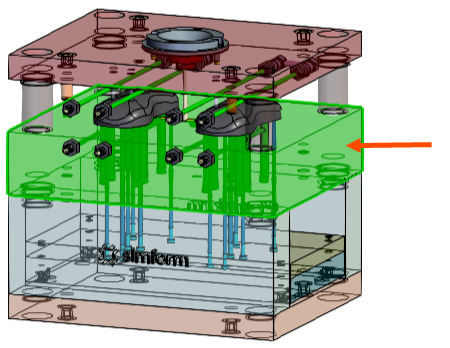

In the display window, select the mold core.

-

Click Mold Group

to create an additional mold group.

to create an additional mold group.

-

In the Mold Group 2 card, click add

to assign the core as a part of the mold group 2.

to assign the core as a part of the mold group 2.

-

Click hide

to hide the categorized component.

to hide the categorized component.

-

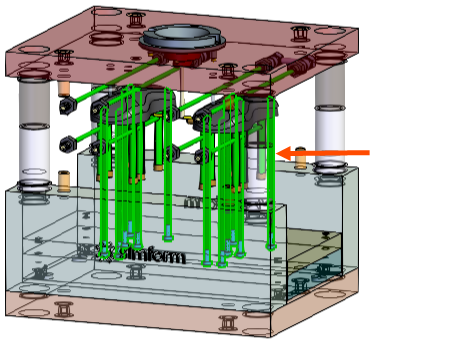

Repeat steps 6 and 7 to select the ejector pins and add them as a part of the

Mold Group 2.

You must categorize all components in contact with the plastic part into one of the mold groups to ensure accurate temperature results. Excluding them from the analysis creates additional sources of cooling that distorts the temperature results and the cooling time estimation.

- In each Mold Group card, expand the Select Material list and select P20 Mold Steel to define the mold material.