View the recommendation results

Display the recommended cooling regions and inspect the plastic temperature to identify where cooling is most needed.

- Click Results to open the results page.

-

In the Display Mode panel, from the

Results list, make sure

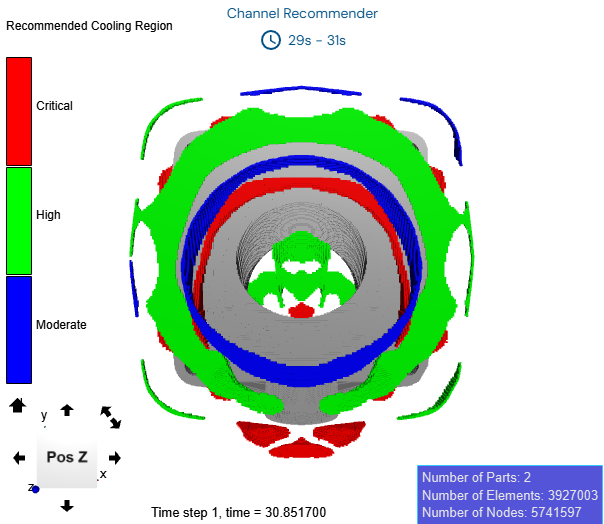

Recommendation is selected.

Recommended cooling regions are shown and color-coded by priority.a

-

Rotate the model to inspect the recommendation results inside the plastic

part.

- On the Display Mode panel, select Filter Plastic.

-

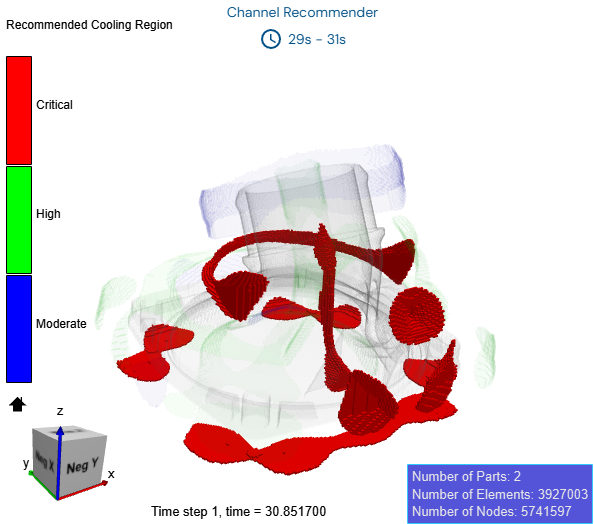

Move the Channel Recommended Region Priority slider to

Critical to filter the display to focus on critical

areas.

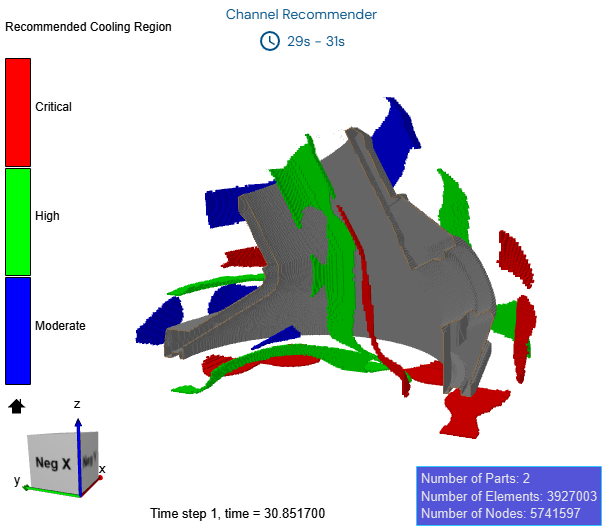

- On the Display Mode panel, select Cutting Plane.

-

Click the X button to examine interior regions.

Make sure that the Clip Plastic Part check box is selected.

-

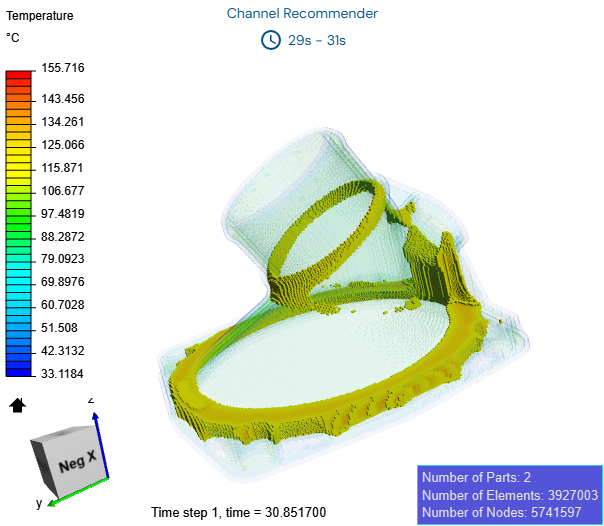

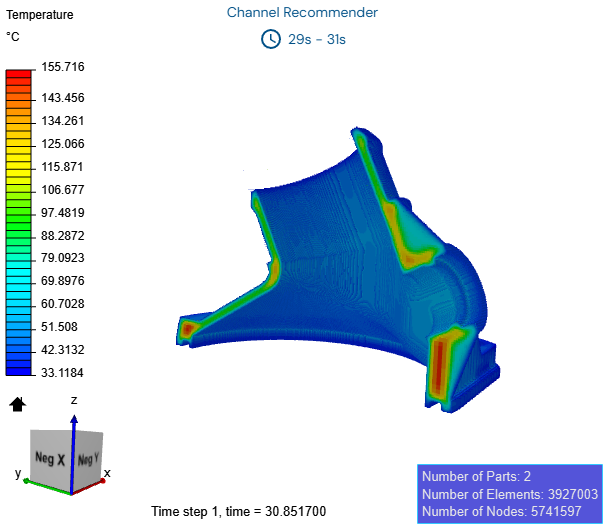

From the Results list, select Plastic

Volume to view the temperature distribution.

-

On the Display Mode panel, select Filter

Plastic and move the slider to 110°C.

The software displays areas where the plastic temperature exceeds the slider value. This helps you identify regions that require longer cooling to reach the target temperature.